1. Repair procedure without pipe flow

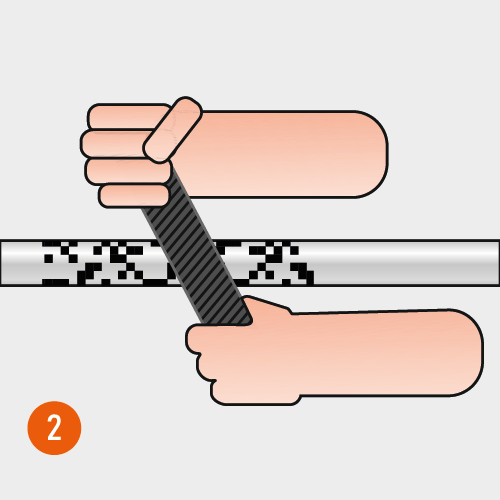

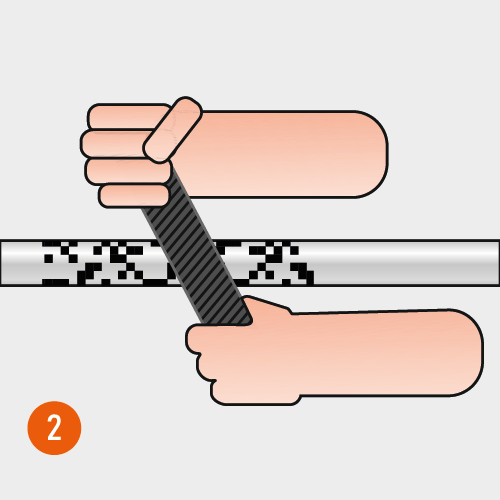

Step 2:

Dull the surface that is to be repaired using a file or sandpaper. In case of PVDF, polyethylene and polypropylene pipes, use a saw blade to get the chequered pattern required.

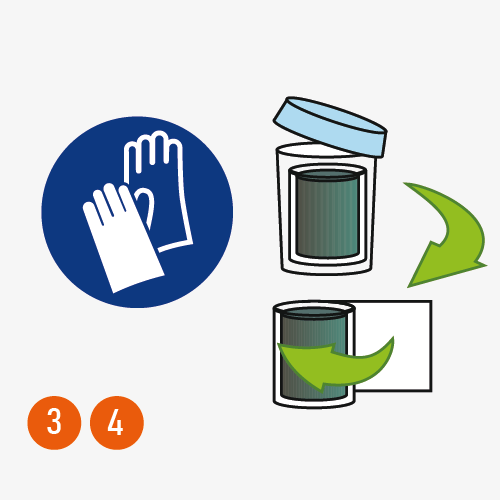

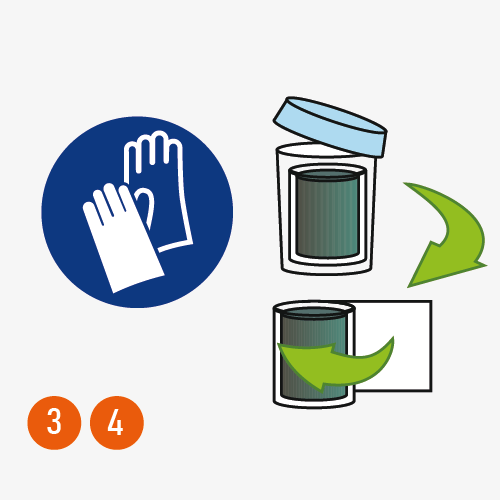

Step 3:

Put on the latex gloves.

Step 4:

Take the epoxy putty out of the sealed plastic bag. Remove the protective film.

Step 5:

Mold the epoxy putty until it is smooth and dark grey and until it becomes warm (approx 20 seconds).

Step 6:

Apply the epoxy putty to the leak so that it fills the holes and cracks.

Step 7:

Fill the prepared container with water.

Step 8:

Rip the aluminium bag apart along the incision. Take out the bandage and dip it in the water for 5 seconds. Squeeze firmly the roll of bandage twice and take it out of the water.

Step 9:

Apply it quickly because the time of application is max. 2 minutes. Wrap the bandage tightly and carefully around the surface under repair. Use the entire roll of bandage.

Step 10:

Tear off the plastic tube from the end of the roll.

Step 11:

Dip the gloves in water and quickly press the resin bubbles back into the bandage wrapped surface, smoothing the area with precise backward and forward movements.

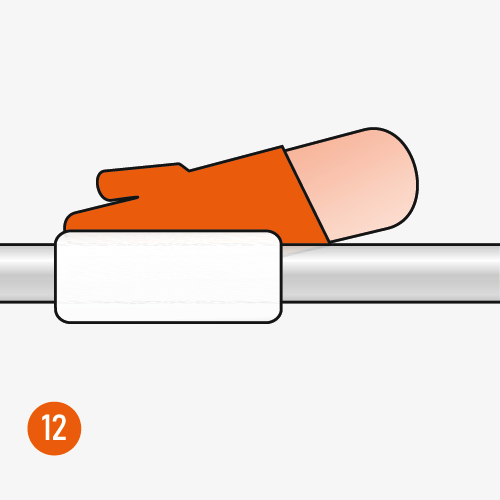

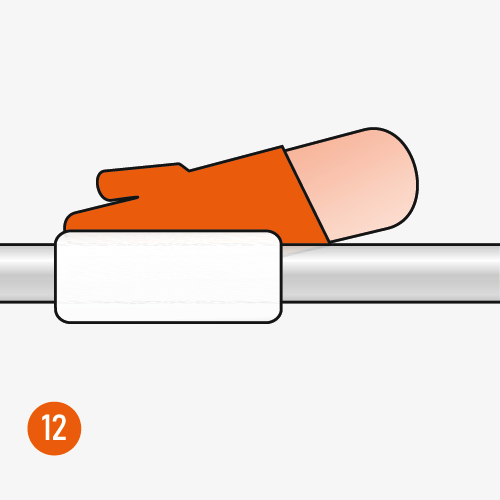

Step 12:

Smooth the wrapped bandage until no bubbles appear (approx. 3 to 5 minutes). After application, the entire part of the repaired pipe should be smooth and ivory in colour.

ATTENTION

- The pipe repair kit is best applied to rough surfaces. Remove any loose rust from the pipe before application.

- A couple of rolls of bandage can be applied in one place if needed. (refer to measurement table).

- In case of leakage at tee-joint, shape the epoxy putty in your hands into a thin roll and wrap it around the tee-joint. Use your fingers to press the putty evenly onto the joint before applying the bandage. It is important that putty fills the gap around the tee-joint completely in order to apply the bandage tightly.

2. Repair procedure with pipe flow

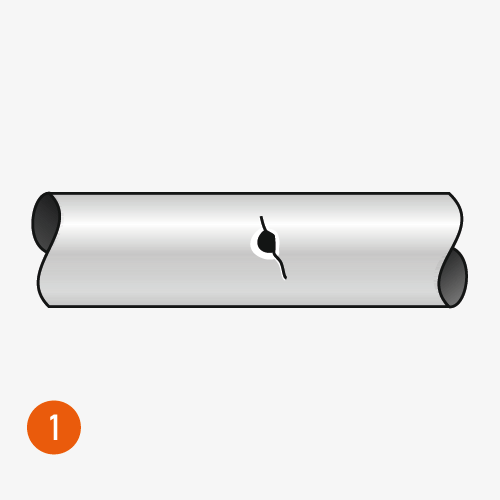

Step 1:

The repair kit can be installed if the leakage pressure does not exceed approx. 1,3 bar.

Step 2:

Dull the surface that is to be repaired using a file or sandpaper. In case of PVDF, polyethylene and polypropylene pipes use a saw blade to get the chequered pattern required.

Step 3:

Put on the latex gloves.

Step 4:

Take the epoxy putty out of the sealed plastic bag. Remove the protective film.

Step 5:

Mold the epoxy putty until it is smooth and dark grey and until it becomes warm (approx 20 seconds).

Step 6:

Apply the epoxy putty to the leak so that it fills the holes and cracks.

Step 7:

Fill the prepared container with water.

Step 8:

Rip the aluminium bag apart along the incision. Take out the bandage and dip it in the water for 5 seconds. Squeeze firmly the roll of bandage twice and take it out of the water.

Step 9:

Apply it quickly because the time of application is max. 2 minutes. Wrap the bandage tightly and carefully around the surface under repair. Use the entire roll of bandage.

Step 10:

Tear off the plastic tube from the end of the roll.

Step 11:

Dip the gloves in water and quickly press the resin bubbles back into the bandage wrapped surface, smoothing the area with precise backward and forward movements.

Step 12:

Smooth the wrapped bandage until no more bubbles appea (approx. 3 to 5 minutes). After application the entire part of the repaired pipe should be smooth and ivory in colour.

ATTENTION

- The pipe repair kit is best applied to rough surfaces. Remove any loose rust before application.

- A couple of rolls of bandage can be applied in one place if needed. (refer to measurement table).

- In case of leakage at tee-joint, shape the epoxy putty in your hands into a thin roll and wrap it around the tee-joint. Use your fingers to press the putty evenly onto the joint before applying the bandage. It is important that putty fills the gap around the tee-joint completely in order to apply the bandage tightly.